Thermal Debinding Kinetics of Gelcast Ceramic Parts via a Modified Independent Parallel Reaction Model in Comparison with the Multiple Normally Distributed Activation Energy Model | ACS Omega

New processing route for ZrSiO4 by powder injection moulding using an eco-friendly binder system | Boletín de la Sociedad Española de Cerámica y Vidrio

Thermal debinding behavior of a low-toxic DMAA polymer for gelcast ceramic parts based on TG-FTIR and kinetic modeling - RSC Advances (RSC Publishing) DOI:10.1039/C9RA00305C

Investigations on thermal debinding process for fine 316L stainless steel feedstocks and identification of kinetic parameters from coupling experiments and finite element simulations - ScienceDirect

e Mass loss of the binder during solvent debinding in parts of AISI M2.... | Download Scientific Diagram

Schematic representation of the shaping, debinding, and sintering (SDS)... | Download Scientific Diagram

Theory and practice of rapid and safe thermal debinding in ceramic injection molding - Xie - 2020 - International Journal of Applied Ceramic Technology - Wiley Online Library

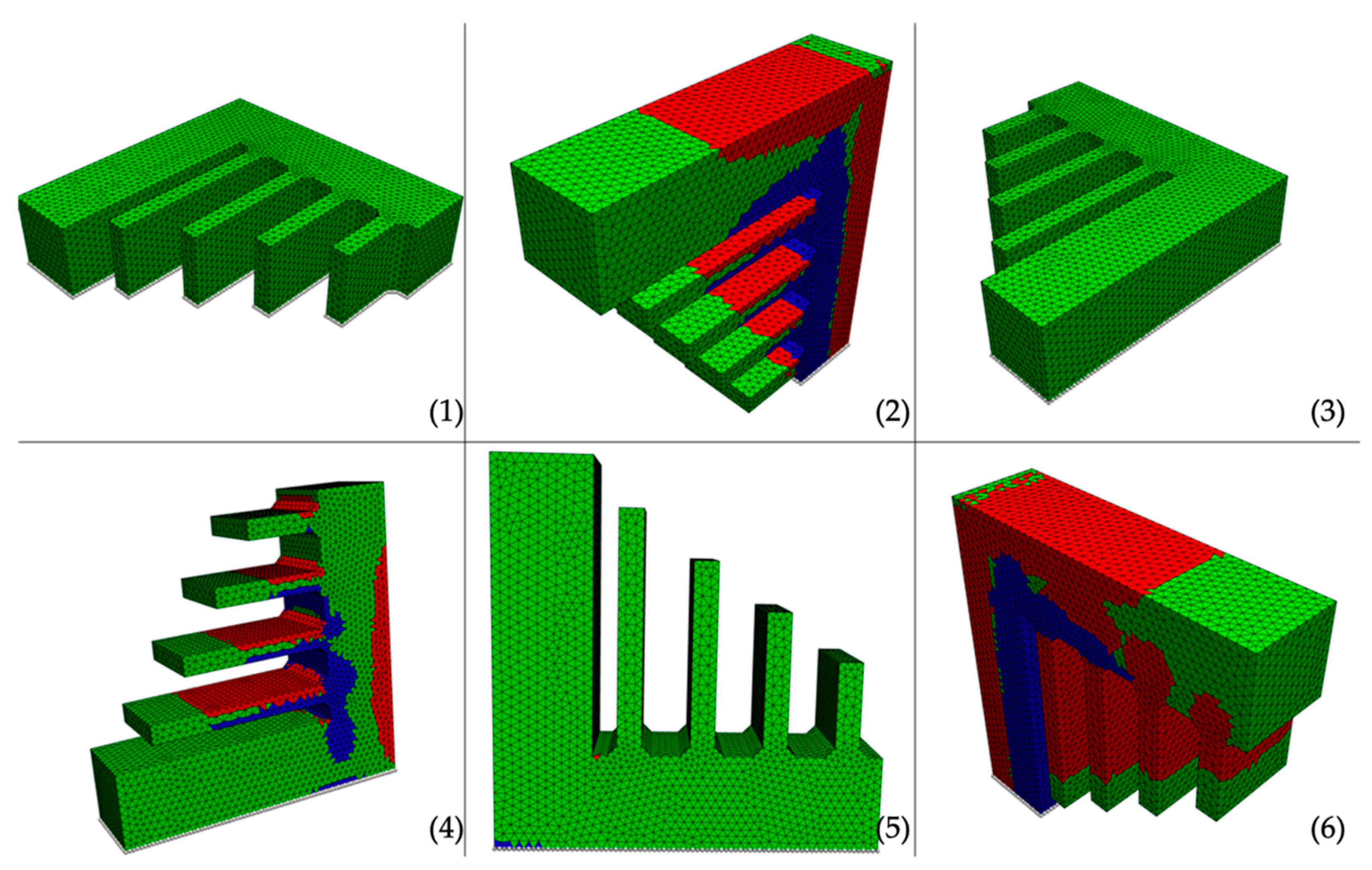

Designs | Free Full-Text | An Automated Open-Source Approach for Debinding Simulation in Metal Extrusion Additive Manufacturing | HTML

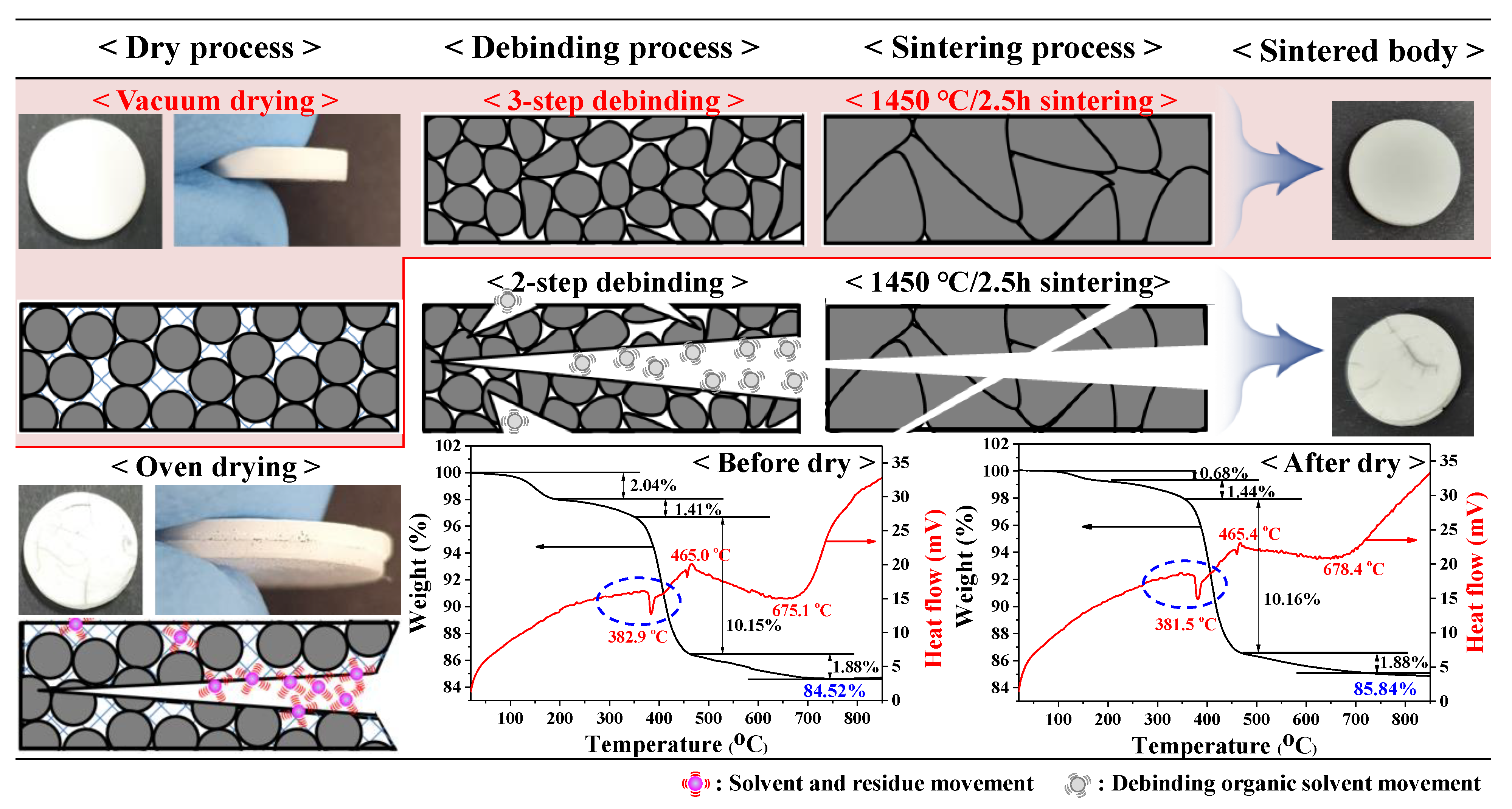

Nanomaterials | Free Full-Text | Sintering Process Optimization for 3YSZ Ceramic 3D-Printed Objects Manufactured by Stereolithography | HTML

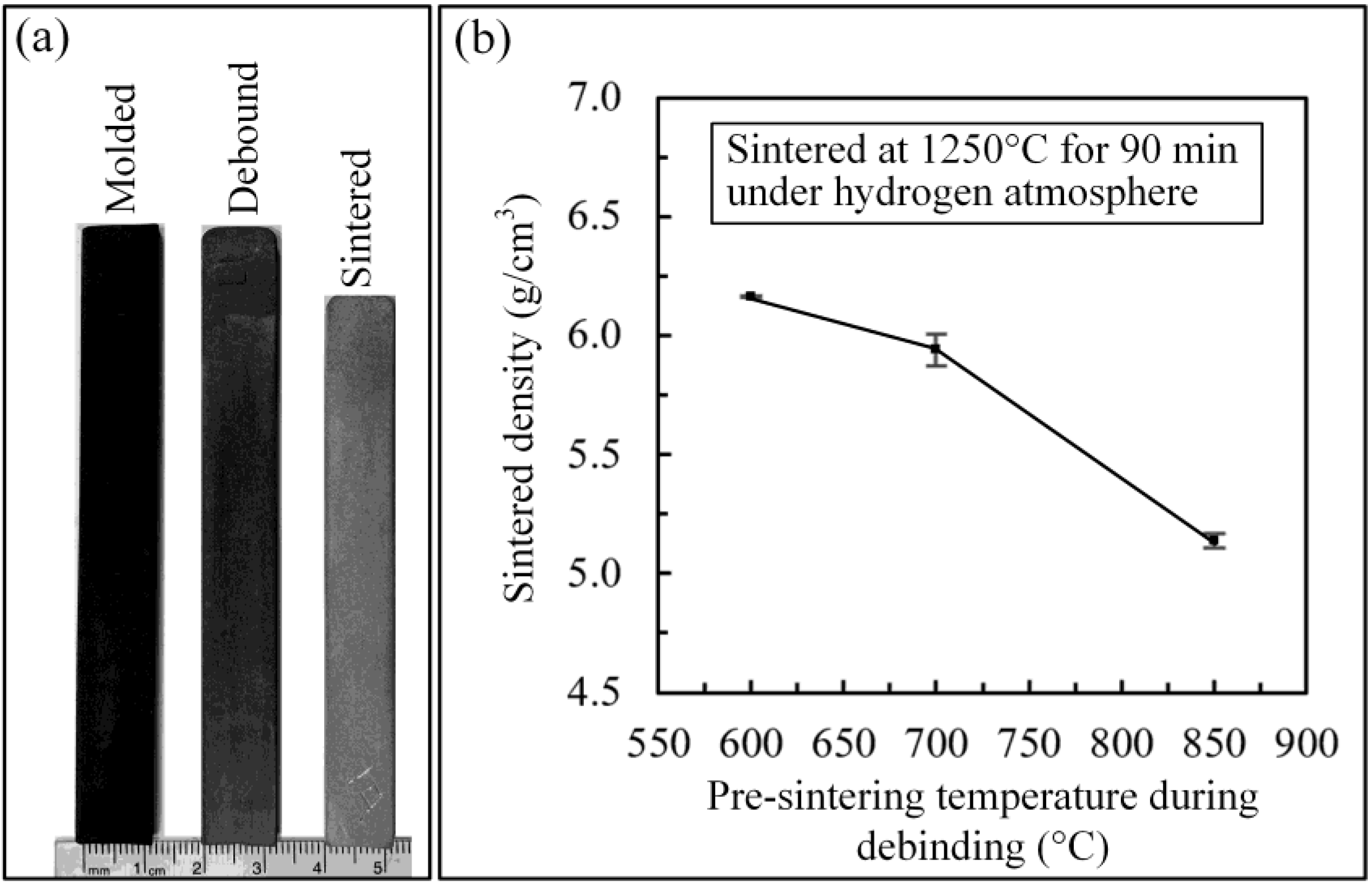

Metals | Free Full-Text | Effect of Thermal Debinding Conditions on the Sintered Density of Low-Pressure Powder Injection Molded Iron Parts | HTML

New insights on the porous network created during solvent debinding of powder injection-molded (PIM) parts, and its influence on the thermal debinding efficiency - ScienceDirect

Additive manufacturing of zirconia parts by fused filament fabrication and solvent debinding: Selection of binder formulation - ScienceDirect

New processing route for ZrSiO4 by powder injection moulding using an eco-friendly binder system | Boletín de la Sociedad Española de Cerámica y Vidrio

![PDF] Effects of binder systems for metal injection moulding | Semantic Scholar PDF] Effects of binder systems for metal injection moulding | Semantic Scholar](https://d3i71xaburhd42.cloudfront.net/9a15bcc35791bcdb72e5da066a34964ab0d4067d/8-Figure1-1.png)

![PDF] Effects of binder systems for metal injection moulding | Semantic Scholar PDF] Effects of binder systems for metal injection moulding | Semantic Scholar](https://d3i71xaburhd42.cloudfront.net/9a15bcc35791bcdb72e5da066a34964ab0d4067d/35-Table3-1.png)

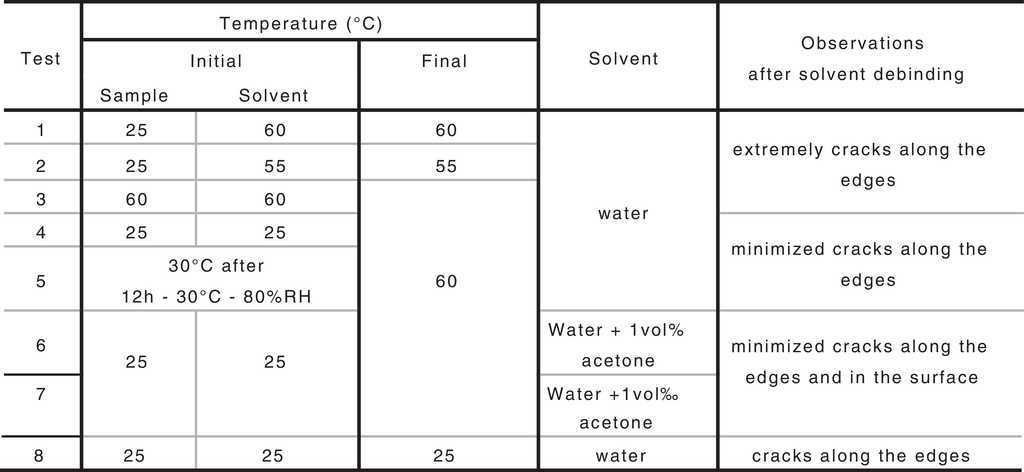

![PDF] Effects of binder systems for metal injection moulding | Semantic Scholar PDF] Effects of binder systems for metal injection moulding | Semantic Scholar](https://d3i71xaburhd42.cloudfront.net/9a15bcc35791bcdb72e5da066a34964ab0d4067d/37-Table5-1.png)